VictoryPCB, well – a well-known manufacturer of computer components and printers, is gearing up for a great start. The company has already created a niche market – for the production of printed circuit boards. In addition, these products are all made of superior-quality printed, electronic materials, computer cases, motherboards, computers, mice, keyboards, all very durable. These materials supply silicone, PC muscle, glass, and copper components.

Copper As Being Sensitive Material

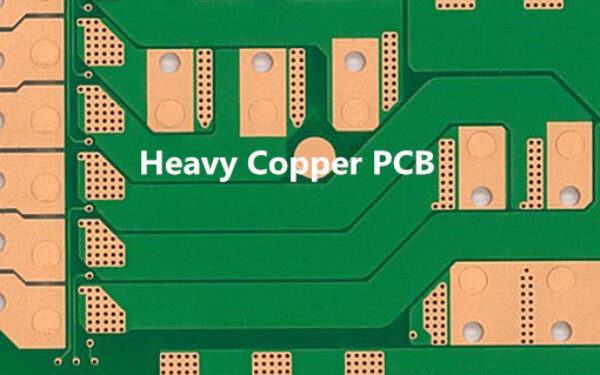

Delicate material is copper, used in a PC cardboard packaging for durability and reliability. This equipment is also used in the main product. Copper strips, copper pipes, and many other PC board components are used to create high-quality products.

High Conductivity Of Copper

With the advent of computers, the requirement for PC board manufacturing has also increased a lot. Today, almost every manufacturer is using this material to produce their products. Copper is mainly used because of its high conductivity level, enabling the circuit to function at a higher speed. VictoryPCB heavy copper PCB also has excellent thermal conductivity, and hence, it is also used to manufacture heat dissipation components for notebooks, personal computers, and other electronic devices. In addition, this material is also used in industrial production where heat dissipation is necessary.

Why is Victory PCB Good at it?

VictoryPCB uses a unique PCM material that is closely related to providing the highest thermal conductivity. They developed a process called new PCM technology that allowed the production of this amazing material. Heat treatment and solvent in PCM process, diffusion is a combination of several technologies. The PCM process provides high resistance to moisture, temperature differences, and abrasion, and the components are always good. Therefore, the material used in PC cardboard packaging is always free from moisture, temperature differences, and abrasion.

Process of Copper Plating And Assembling

Copper foam is made by cold rolling or hot dipping of the plate by two forming processes. In both methods, make sure the foam sheet motherboard is fitted correctly. It should be noted that foam thickness is not a constant factor and may vary due to various factors. This simplifies things for creating as well as for personalization.

When the VictoryPCB is filled with PCB material, assembly begins. The printed, electronic packaging company uses a special sponge to apply the surface material on the board. It is also possible to apply directly on board, following the manual application process provided by the material manufacturer. This allows the entire surface to be covered with a material, thus avoiding excess adhesive during packaging procedures.

Final Thoughts

PC manufacturers have simplified the whole board process and made it easier for people to stock up on the items they need. Online stores offer competitive prices and fast delivery. It is easy to shop and choose a reputable supplier product in a major way. This source reduces the time required and provides customers with the best deals. These advantages and features of PCB packaging definitely make it a popular choice and make it beneficial for businesses in need.